The UFCW Occupational Safety and Health Office has released a guide that lists the workplace hazards that may occur in a retail workplace. The hazards listed in the guide are all violations of the standards set forth in the Occupational Safety and Health Administration (OSHA), and should be immediately reported to a supervisor and a union steward or union representative.

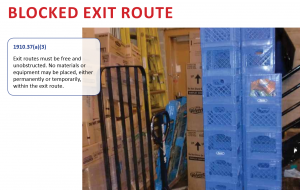

The guide, which can be accessed on the UFCW Safety and Health website, provides photos of examples of the hazards that violate OSHA standards, in order to help workers and supervisors identify and eliminate workplace hazards.